Snacks Processing Unit

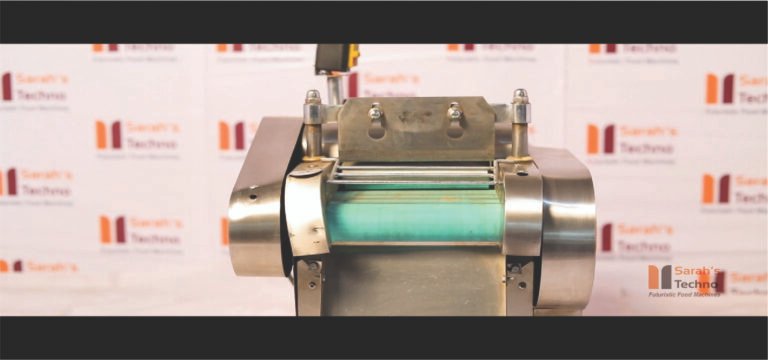

Vegetable Cutter

The vegetable cutter is a versatile machine designed for high-capacity cutting, with a processing range of 200 kg to 1000 kg per hour. It is powered by a motor between 1 HP and 3 HP, available in both single-phase and three-phase options. Made with SS304L stainless steel for all contact parts, the cutter ensures durability and hygiene. It features interchangeable cutting blades, allowing for adjustable cutting thicknesses from 1 mm to 10 mm and beyond, making it suitable for a variety of vegetable preparations. With a power range of 1 kW to 2.5 kW, the machine can operate in both manual and automatic modes, providing flexibility for different operational needs in food processing industries.

| Vegetable Cutter | |

|---|---|

| Capacity | 200 kg - 1000 Kg / hr |

| Motor | 1 HP - 3HP (single phase or 3 phase) |

| Material (MOC) | SS304L (Contact Parts) |

| Cutting Blades | Interchangeable |

| Cutting Thickness | 1mm to 10mm and more |

| Power | 1KW to 2.5KW |

| Operation | Manual / Automatic |

Vegetable Washer

The vegetable washer is designed for efficient cleaning of vegetables, with a capacity range of 200 kg to 1000 kg per hour. It is powered by a motor ranging from 1 HP to 3 HP, available in both single-phase and three-phase options. Constructed with SS304L stainless steel, the washer ensures durability and hygiene. The machine can be operated in both manual and automatic modes, offering flexibility for different washing needs. This washer is ideal for use in food processing facilities where large volumes of vegetables need to be cleaned efficiently and thoroughly.

| Vegetable Washer | |

|---|---|

| Capacity | 200 kg - 1000 Kg / hr |

| Motor | 1 HP - 3HP (single phase or 3 phase) |

| Material (MOC) | SS304L |

| Operation | Manual / Automatic |

Pellet Stove

The pellet stove is a highly efficient heating solution, generating between 30,000 to 50,000 BTU of heat per hour. It is powered by a motor ranging from 1 HP to 3 HP, available in both single-phase and three-phase options. Made from durable cast iron, the stove is built to withstand high temperatures and ensure longevity. The pellet hopper can hold 40 to 80 pounds of pellets, providing 16 to 48 hours of continuous burn time, depending on the burn rate. With burning efficiency ranging from 75% to 90%, the stove offers effective fuel usage. The pellet stove can operate in both manual and automatic modes, providing flexibility for various heating needs. It is ideal for residential or small commercial heating applications.

| Pellet Stove | |

|---|---|

| Capacity | 30000 - 50000 btu (heat generated in hour) |

| Motor | 1 HP - 3HP (single phase or 3 phase) |

| Material (MOC) | Cast Iron |

| Pellet hopper capacity | 40-80 pounds 16 - 48 hours of continous burn time |

| Burning Effeciency | 75%-90% |

| Operation | Manual / Automatic |

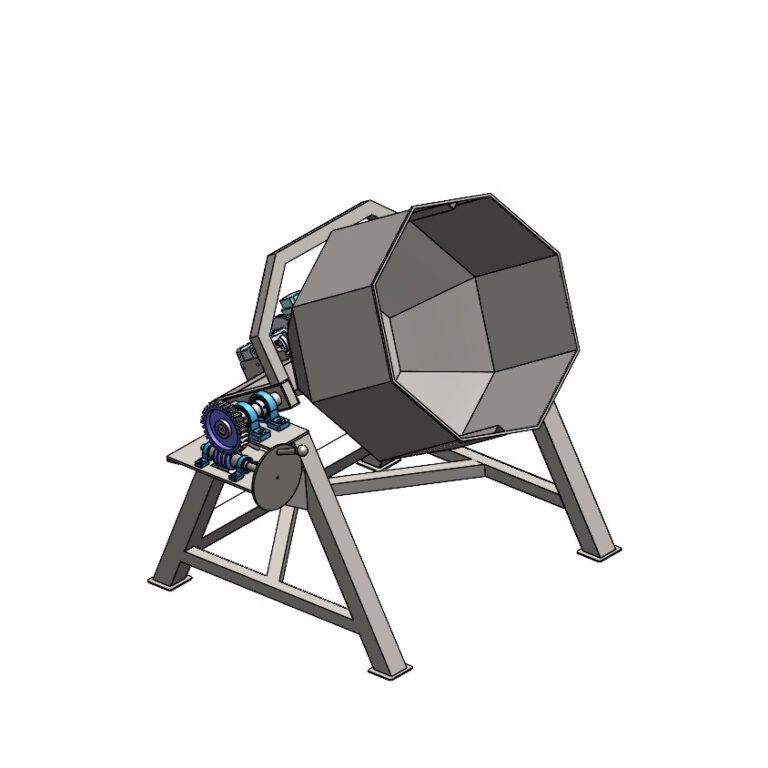

Flavouring Machine

The flavoring machine is designed for evenly coating or flavoring products, with a capacity range of 5 kg to 300 kg per batch. It operates with a motor power between 1 HP and 5 HP, and is equipped with a Variable Frequency Drive (VFD) to provide adjustable speed control. Made from SS304L stainless steel, the machine ensures durability and hygiene. It can operate in both manual and automatic modes, offering flexibility for different production scales. The flavoring machine is ideal for use in food processing industries, particularly for coating snacks, nuts, or other food products with seasonings or flavors.

| Flavouring Machine | |

|---|---|

| Capacity | 5kg to 300kg / batch |

| Motor | 1 HP - 5HP (single phase or 3 phase) |

| Motor | VFD provided |

| Material (MOC) | SS304L |

| Operation | Manual / Automatic |

De Oiling Machine

The de-oiling machine is designed for efficiently removing excess oil from various products, with a capacity ranging from 5 kg to 500 kg per batch. Powered by a motor between 0.5 HP and 5 HP, it offers both single-phase and three-phase options. Constructed from SS304L stainless steel, the machine ensures durability and hygiene. Featuring a centrifugal automatic de-oiling mechanism, it achieves oil removal efficiency of 95% to 98%, with a basket diameter ranging from 400 mm to 800 mm and operating at speeds of 300 to 600 RPM. The machine can be operated in both manual and automatic modes, making it ideal for use in food processing industries where oil reduction is required, such as for snacks, fried foods, or other oil-coated products.

| De Oiling Machine | |

|---|---|

| Capacity | 5kg to 500kg / batch |

| Motor | 0.5 HP - 5HP (single phase or 3 phase) |

| Material (MOC) | SS304L |

| Design | Centrifugal automatic de oiling mechnism |

| De oiling effeciency | 95%-98% |

| Basket diameter | 400mm to 800mm |

| RPM | 300-600 |

| Operation | Manual / Automatic |