Pickle Processing Unit

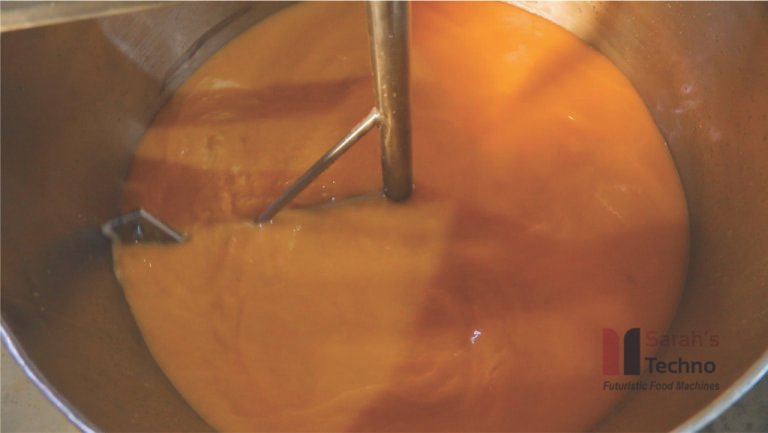

Concentrator

Sarah’s Techno’s Concentrator is a versatile machine designed for efficient liquid processing. With capacities ranging from 100 to 1200 liters, it can handle various production needs. The concentrator’s robust stainless steel construction ensures durability and long-lasting performance. Powered by a 4KW to 32KW motor, it provides ample power for concentrating liquids like pickle gravy and can also be used as a blender for smaller quantities.

| Concentrator | |

|---|---|

| capacity | 100ltr to 1200ltr |

| Materials (MOC) | SS304L |

| Power | 4KW TO 32KW |

| Purpose | Concentration of pickle gravy / act as blender for small quantity |

Ribbon Blender

Sarah’s Techno’s Ribbon Blender is a versatile and efficient mixing machine designed for food processing applications. With a capacity range of 100 to 1200 liters, it can handle large batches of ingredients effectively. The blender’s robust stainless steel construction ensures durability and long-lasting performance. Powered by a 2HP-5HP motor, it provides ample power for mixing various products, including pickles, gravy, and other food mixtures.

| Ribbon Blender | |

|---|---|

| Capacity | 100ltr to 1200ltr |

| Materials (MOC) | SS304L |

| Power | 2HP-5HP |

| Purpose | Mixing of pickle with gravy |

Paddle Blender

Sarah’s Techno’s Paddle Blender is a versatile and efficient mixing machine designed for food processing applications. With a capacity range of 100 to 1200 liters, it can handle large batches of ingredients effectively. The blender’s robust stainless steel construction ensures durability and long-lasting performance. Powered by a 2HP-5HP motor, it provides ample power for mixing various products, including pickles, gravy, and other food mixtures.

| Paddle Blender | |

|---|---|

| Capacity | 100ltr to 1200ltr |

| Materials (MOC) | SS304L |

| Power | 2HP-5HP |

| Purpose | Mixing of pickle with gravy |

Vertical Blender

Sarah’s Techno’s Vertical Blender is a powerful and versatile machine designed for efficient food processing. With capacities ranging from 100 to 1200 liters, it can handle large batches of ingredients with ease. The blender’s robust stainless steel construction ensures durability and long-lasting performance. Powered by a 2HP-5HP motor, it delivers ample power for mixing a variety of products, including pickles, gravy, and other food mixtures.

| Vertical Blender | |

|---|---|

| Capacity | 100ltr to 1200ltr |

| Materials (MOC) | SS304L |

| Power | 2HP-5HP |

| Purpose | Mixing of pickle with gravy |

Filling Machine

Sarah’s Techno’s Filling Machine is a precise and efficient solution for filling pickle with gravy. With a capacity of 100g to 1kg, it can accurately fill containers at a speed of 30 bottles per minute. The machine features a durable stainless steel construction and is equipped with high-quality pneumatic components from Festo Germany. Its user-friendly design and reliable performance make it an ideal choice for food processing applications.

| Filling Machine | |

|---|---|

| Capacity | 100g to 1kg |

| Filling accuracy | 5g |

| Filling speed | 30 bottles / min |

| Pneumatic items | Festo German |

| Hopper Capacity | 40kg |

| Machine Finish | Matt & Mirror |

| Operating Voltage | 230V |

| Materials (MOC) | SS304L |

| Power | Single phase |

| Compressor | 2HP |

| Purpose | Mixing of pickle with gravy |

Lemon Cutting Machine

Sarah’s Techno’s Lemon Cutting Machine is a high-speed solution for efficient lemon processing. It can cut up to 150 lemons per minute, producing either 4 or 6 pieces per lemon, depending on the desired size. The machine features a sleek stainless steel design and is available in both matt and mirror finishes. Powered by a 2HP-5HP motor, it delivers reliable and consistent performance for various food service and processing applications.

| Lemon Cutting Machine | |

|---|---|

| Capacity | 150 lemon / 1 min |

| Number of pieces | 4 / 6 |

| Number of head | 4 / 6 |

| Machine Finish | Matt & Mirror |

| Materials (MOC) | SS304L |

| Power | 2HP-5HP |

| Purpose | Cutting lemon for pickle |

Bowl Chopper

Sarah’s Techno’s Bowl Choppers are versatile machines designed for efficient food processing. With capacities ranging from 5 to 200 liters, these choppers can handle various production needs. Equipped with multiple blades and adjustable speeds, they excel at chopping and mixing a wide range of food products, including sausages, meat emulsions, pastes, and purees. The robust stainless steel construction and integrated safety features ensure durability and reliable operation in food processing environments.

| Bowl Chopper | |

|---|---|

| Capacity | 5 litre to 200 litre |

| No.blades | 2 to 6 |

| Blade speed | 1500 or 4000 rpm |

| Bowl Rotation Speed | 10-30 rpm |

| Materials (MOC) | SS304L |

| Power | 3 - 20KW |

| Safety features | equipped with safety covers and sensors to ensure the machine only operates when the lid is securely closed |

| Purpose: | Used in the production of sausages / meat emulsions / pastes / purees and other food products requiring fine chopping and mixing. |

Steam Based Kettle

Sarah’s Techno’s steam-based kettles are versatile and efficient cooking and heating equipment. Constructed with high-quality stainless steel, these kettles offer a wide range of capacities to suit various production needs. Powered by steam, they provide precise temperature control for cooking and processing a variety of products, including sauces, soups, dairy, and jams. The kettles incorporate safety features like pressure relief valves and interlocks to ensure safe operation and protect against potential hazards.

| Steam Based Kettle | |

|---|---|

| Materials (MOC) | SS304L |

| Capacity | 50 ltr to 1000ltr {depending on application} |

| Power | steam with pressure typically between 1 to 10 bar |

| Heat jacket pressure | 1 to 3 bar pressure |

| Type | Scraper - 1. agitator 2. anchor agitator 3. propeller-type agitator |

| Speed | Variable speed ranging from 15 to 100 rpm |

| Power of agitator motor | 1 KW to 5 KW |

| Steam Consumption | Depends on capacity; Eg: a 200-litre kettle might consume around 15 to 20 kg / hr of steam |

| Insulation | Outer surface covered with insulating material to reduce heat loss and improve energy efficiency |

| Tilting Mechanism (if applicable) | Manual or motorised tilting for easy product discharge Temperature control. Steam control valve with temperature settings ranging from 50°C to 120°C |

| Safety features | 1. pressure relief valve 2. safety interlock for the agitator 3. over-temperature cut-off |

| Applications | Used for cooking / boiling or heating products like sauces / soups / dairy / jams / and other viscous liquids in food processing industries |